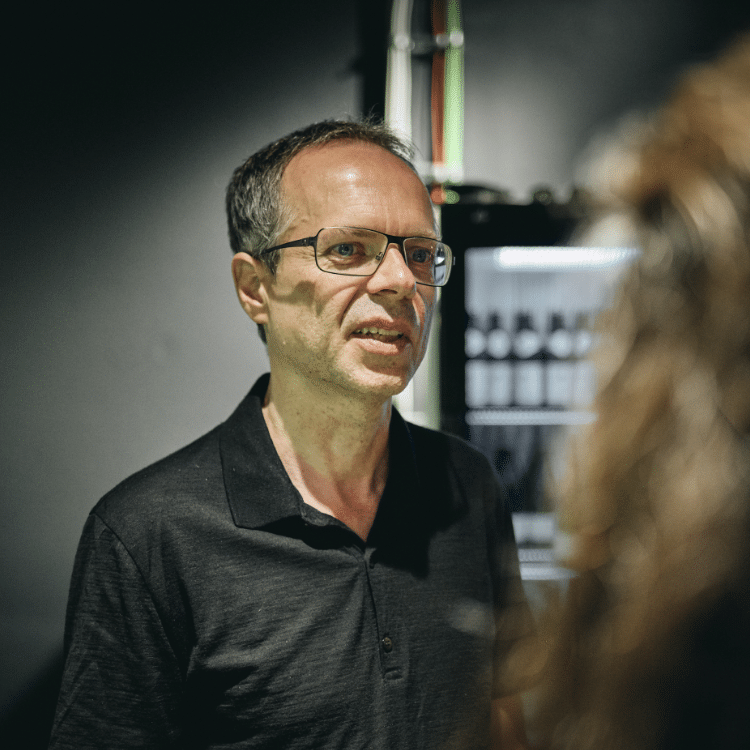

INGO RÜTTEN

GESCHÄFTSFÜHRUNG

Die Strategieberatung in Frankfurt

„In disruptiven Zeiten stehen Unternehmen, Organisationen und Menschen vor vielfältigen Herausforderungen.

Wir finden Antworten auf Ihre Zukunftsfragen und unterstützen Sie bei der Zielerreichung.

Mit umsetzungsorientierter Strategieberatung, kreativer Markenkommunikation, agiler Innovationsentwicklung. Mit bewährten Prozessen und unserem interdisziplinären Expertennetzwerk. Inhabergeführt. Persönlich. Seit 2003.“

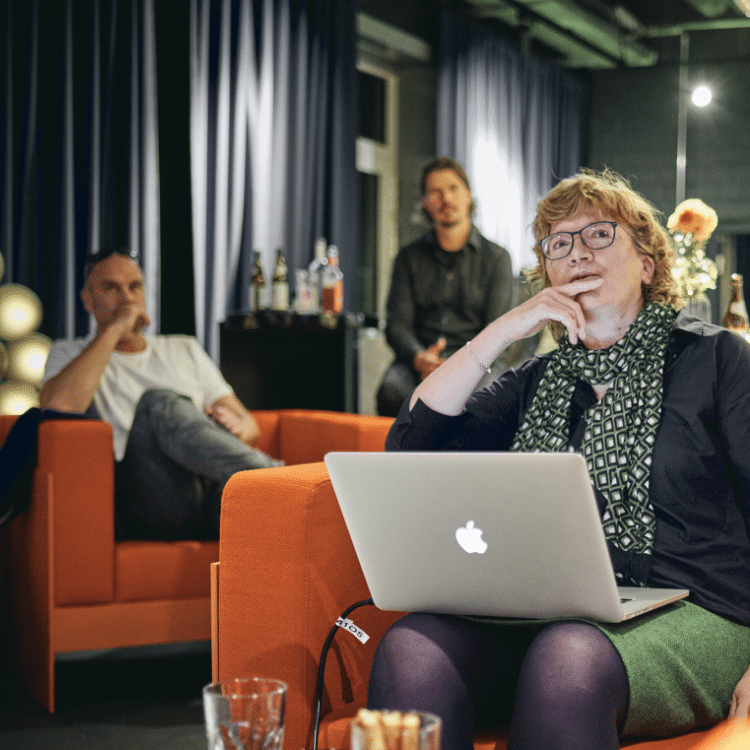

UNSER TEAM

INTERDISZIPLINÄR. FEST & FREI. MIT EXPERTISE UND LEIDENSCHAFT.

UNSER LEISTUNGSPORTFOLIO:

UMSETZUNGSORIENTIERTE

STRATEGIEBERATUNG

- Marken- & Kommunikationsstrategien

- Unternehmensstrategie (Mission, Vision)

- Marketingplanung

- Markt- & Wettbewerbsanalyse

- Zielgruppen und Personas

- Pitch-Consulting

KREATIVE

MARKENKOMMUNIKATION

- Kampagnenentwicklung

- Kreativkonzeption

- Interne Kommunikation

- Corporate Design & Digital Branding

- Content Marketing

- Whitepapers, Blogs, Studien, Webinare

AGILE ORGANISATIONS- &

INNOVATIONSENTWICKLUNG

- New Work/Change-Beratung

- Employer Branding

- Corporate Purpose

- Business Development

- Produktentwicklung & Trendscouting

- Digitale Transformation & Digitalstrategien

UNSER ANGEBOT:

VOM SPONTANEN IMPULS BIS ZUR NACHHALTIGEN ZUSAMMENARBEIT.

IMPULS

Vortrag, Workshop, Sparring oder Kamingespräch zu Ihrer Zukunftsfrage

PROJEKT

Erreichung Ihres Zieles in klar definiertem Zeit- und Kostenrahmen

PROZESS

Beratung für nachhaltige Marken- und Organisationsentwicklung

WELCHE ZUKUNFTSFRAGE BEWEGT SIE?

WELCHE ZUKUNFTSFRAGE BEWEGT SIE?